So you think you’re analog, eh? You always use physical faders for your volume swells, you only record to tape, and you have that nifty vibrato guitar pedal with a BBD IC chip. I call bullshit. That’s not analog enough! An IC chip? Well, domo arigato, Mr. Roboto, but no arigato. If you want that pedal to be even more analog, you need to send your guitar signal through an aluminum disc covered in oil to rubber pickups. WTF? Here’s one of the biggest stomp boxes you’re likely to ever see, the Tel-Ray Morley RWV Rotating Wah.

Raymond Lubow invented the oil can echo in the 1960s for his company, Tel-Ray Electronics, to be a more reliable device than the tape-based echoes of the time. Smaller than a tape echo, it was also able to be added by amplifier manufacturers to their products. It uses an aluminum disc rotating in an electrostatic oil which brushes against conductive rubber pickups to carry the sound. Raymond used the same technology to create the Morley rotating speaker simulator and shove it into a pedal. The name was a pun on the Leslie (less-lee) rotating cabinet speaker. Thus a company was born and we all got ever-so confused. Now imagine you have a broken one. Fuck.

I was given this obsession with Morley by a former bandmate. He also had a Morley RWV and I wanted one. Culling eBay, I finally got one, but it had some issues. The previous owner had actually cleaned up the insides nicely, but had used his wife’s hairband for the belt-drive and it wouldn’t start right. Luckily, when I manually spun it, it sounded clean. One problem with these old oil can devices is that if the anodized aluminum disc inside the can gets scratched, it creates an annoying tick and there are NO replacements available. That wasn’t a problem here, but opening the case just to nudge the motor into working was. I was going nuts… or rather, I’d lost a nut.

I opened the box containing the oil can and motor and found a loose nut and its washer. I found it had come loose from the motor mooring and was impeded the motors spin. Oh-so-conveniently, this nut belonged behind the band wheel that spun the disc inside the oil can. The band wheel did not come off separately, so for one fucking measly little loose nut, I had to disassemble the entire device.

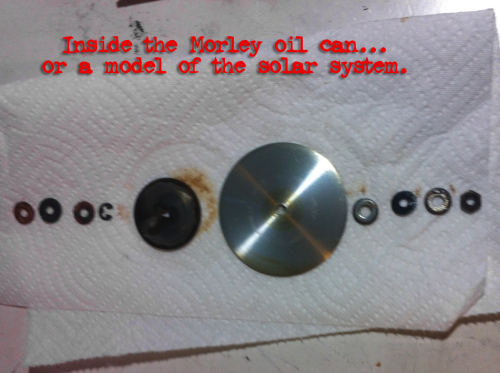

The oil can itself has two removable lids. One is fastened to the motor housing, so I took the whole can off. I should also mention, I carefully saved the oil. It’s one of a kind and necessary for the effect. In the above photo, you can see the disc and the rubber pickups. The pickups come apart in one piece. Getting the axle free is a little more complicated.

I took the parts of the axle and laid them out in order so I wouldn’t fuck up putting them back on. I also carefully swabbed the aluminum disc with a cotton swab and a soft towel to get off the various bits of metal decay that came with some 40 odd years of existence for this pedal.

This is the inside of the oil can the axle and pickups removed. It’s not really an important photo, but it’s fucking cool to see.

With the axle and band wheel removed (and a couple other bolts that keep the housing together) I was able to get at the motor and secure it. Now when it powers up, the electromagnetic motor spins like it was brand new. I replaced the previous owner’s wife’s hairband with a much more appropriate square-rubber belt from Russell Industries, part # 1407-47. It’s available here.

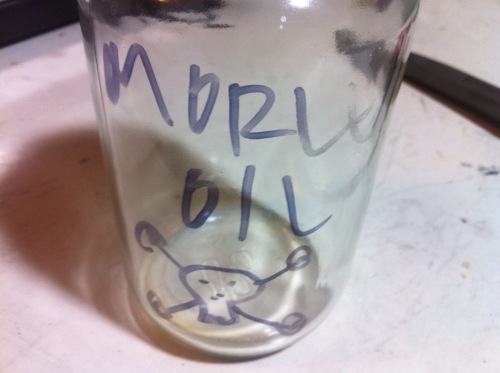

I’d saved the oil from this and a previous oil can repair. It’s called UCON LB-65 and it’s electrostatic properties make it the only oil that works in these things. It’s also super hard to get. There have been various people selling it on eBay, but last I checked, it’s going for almost $90 for four ounces! Shysters! Luckily, these oil can devices only require a tablespoon of the stuff and I had just enough. Just like Mary Poppins said, “a spoonful of UCON LB-65 electrostatic oil makes the medicine go something something.”

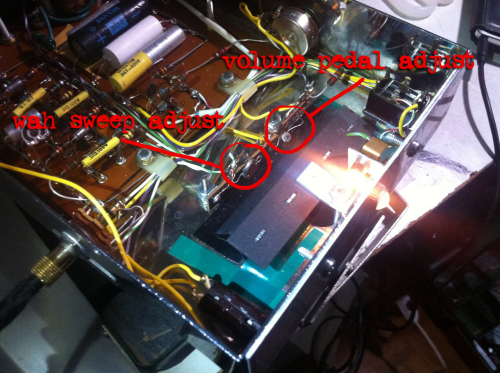

While I was in there, I decided to conduct a full diagnostic. The curtain shielding the LDR that controls the wah and volume was a bit loose, so I fixed it as I have on every Morley so many times before. I also fixed the LDRs that control the wah and volume circuit. They were carefully bent and moved until the curtain attached to the foot treadle sweeps them into the shade with a graceful movement.

Now, the moment of truth: does it god-damn work? Well, true believers, see for yourself and WITNESS the glory of TRUE ANALOG!!!! (and a shitty guitar solo… but hey, that’s why I play bass)

That thing's fkn nutss… but yer still a jerk!

Ain't I a stinkah?

Man, totally kinda random here but I have an old-ass Morley slimline echo/volume that got trashed along with a lotta other gear when I kinda abandoned it in a jam room for a while. I've fixed everything but it, and it's simply a disconnected wire from the on/off switch that's got me stumped. I can't find a schematic or photos, I've dug around for clues online, and you're the only fella who seems hip to the old Morleys.

It's weird, you can't see whatsoever any evidence of the broken connection anywhere, so I'm totally at a loss as to where this hot wire off the switch could go. I couldn't find any info online regarding replacing the power switch or the routing of the wires. When a wire has been loose on other pedals, it's always been so obvious…Crazy.

Anyway, please excuse the long winded reply, but it seems you'd probably have an idea so I was hitting ya up.

Hello! I was wondering If you have any Idea what may be the cause of my pedal overheating after "prolonged use" i mean, When I turn it on my pedal works just fine (when Its cold) but after half an hour being turned on the effects start to fade and The Aluminum box with the can Its REALLY HOT! I suppose the oil gets boiling or something and the whole temperature causes the components to behave differently.

Thanks in advance!

Pedro

this is highly abnormal. The oil should not be heating up in any way. Things to check: 1) the motor spinning the disc. Could need replacing or maybe just new bushings. 2) The transformer. This is inside the smaller box with the foot. It could be ready to give up and might fry up any capacitors. 3) speaking of capacitors, check all of those everywhere and see if any look bulging or are blown. 4) Clean up the entire oil can assembly, could be muck is dragging the motor down or you might possibly not have enough oil. There should be about a tablespoon or 2 in the can.

Hi, thanks for all the great information you provide on your site!

I was wondering if you would happen to know the rpm of the the motor in the RWV? I have one that I’m restoring, but I live in Europe and it would be a lot easier to deal with this box at 220 volts directly instead of with a step-down in front.

🙂

../~howard

Unfortunately, I don’t have a schematic for the RWV… Morley doesn’t provide one like it does it for a lot of its other pedals.

If you wanted to make the pedal 220V ready, I don’t think you need the RPM of the motor. What you need is the DC voltage on the ends of the AC power transformer. Find a transformer equivalent that will change 220V into the equivalent DC required, replace the original with that and voila, you’ve converted your RWV into European standards.

See next comment for reply, I managed to botch the reply… :-p

Hm. I have a transformer for the DC part (I have a Wah and a Phaser that I’ve already converted) and I found the schematic floating around on the tubes, but the motor is 110V AC (directly connected to the power switch), not low voltage or DC.

🙂

Oof. Sorry I don’t have any recommendations for that! I guess you’d need to run an inverter. Replacing that motor would probably be more trouble than it’s worth.

Thanks for being available and caring.

I recently inherited a morley RWV Rotating Wah newly capped and sort of working?!?

Volume goes up both ways from center?

Does anyone make a replacement decal for the top?

Does anyone overhaul/rebuild them.

I use a ventura vibe pedal that does similar but…

Thx,

Gj

I don’t know of anyone who specifically repairs these… I have been to some random repair shop in Portland, OR that was working on one, don’t remember the name. Best bet is to call around to repair shops. And hurry! A lot of old timer repair guys who actually understand this shit are all on the verge of retiring. It’s a disappearing art.

The volume going up both ways from center COULD be just a loose light curtain and easily fixed on your own. Check out this article for more about the light curtain in an old Morley: https://www.doktorsewage.com/mondo-morley-medicale-pwf-power-wah-fuzz/

Hey, nice work. I have one of these monsters. The rotating effect volume stays the same for the entire range of the pot 0-10. Inside is a 25m (25 meg?) solid shaft pot which looks stock. Can you say whether this is the stock value? I can’t find a schematic or info online about this pot.. Let alone a replacement. Thanks for the info, very nice work!

Best from Alaska

It may not be stock. The value should be 100K according to the schematic. You can find that here: https://www.doktorsewage.com/rwves/

https://elektrotanya.com/morley_rwv_rotating_wah_volume_sch.pdf/download.html#dl

hey doc,

greetz from new england across the pond in jesusland.

here’s a linky for the schematic for this suckah. hopeful the above will help some other poor sojourner on their path from the perdition of antique tonal ear abuse.

anyways… back to the utility fuzzbox research kitchen

rock on, dude

pink jimi

HELL YES! Thanks for the share!

hey doc,

i scored one of these puppies on evilbay, its fucked up as a soup sandwich.. the wah part is sublime, but the oil can is gonna need a complete rebuild. even found a replacement motor. gonna give us something for me and my son to work on while we wait the plague clearing. hang in there, mate, wash your hands and rock on!

pink

the parts I hope are okay are the anodized disc and the rubber pickups… everything else is replaceable, even the oil (if you have the money for it) but the discs and pickups are pretty much impossible. if the disc is scratched and making a click noise on the pick up, you can apparently trim the part of the pickup that touches it if the scratch is small enough. good luck

i DO work on these suckers, even got the proper goo for ’em

^ this guy works on these! By all means, share your location, business name, or a way you’d like to be contacted in case some poor soul with a broken one wants talk to you about working on theirs. I get a lot of clicks on this post from people looking for help on these.

ps, i don’t mind working on these, but to be fair, sometimes they are just fucked. no way to get parts unfortunately… but for most applications, if someone is REALLY stuck, they can contact me thru my facebook or youtube

facebook.com/pinkjimiphoton

youtube.com/666pinkster

thanks doc… long may ya rock, mate

i’m in new england usa, always up for consultation with fellow gear whores.

peas!